7 Horrible Mistakes You Can Avoid While Buying a Weighbridge Machine

A weighbridge operator’s worst nightmare? Investing in the wrong weighbridge machine. The collapse of a weighbridge isn’t just about repair costs; it can trigger a cascade of issues. Failing to meet government standards, a malfunctioning weighbridge can lead to substantial downtime, wasted outputs, costly delays, and even hefty penalties.

To help you navigate this crucial purchase, let’s explore the seven most common mistakes before buying a weighbridge machine:

1. Overlooking Structure Weight: The Foundation of Durability

The structural integrity of a weighbridge machine is paramount. Building regulations demand that structures are meticulously planned and constructed to safely withstand all anticipated loads throughout their service life, ensuring optimal operation. Minimum load requirements and structural specifications vary significantly based on weighbridge construction type, geographic location, intended usage, and the materials employed. Don’t compromise on this fundamental aspect; a robust structure is key to long-term reliability.

2. Unnecessary Spending on Spare Parts: Smart Choices Save Money

Many clients find themselves burdened with exorbitant spare parts costs. This can be completely avoided! The solution lies in partnering with well-established Pit Less weighbridge providers. Always source critical components from reputable suppliers. Annually, businesses collectively waste a significant amount on spare parts. Investing in a properly constructed weighbridge machine from the outset is crucial to minimize these gratuitous expenditures. Do your research online to find the best Weighbridge Price that includes quality and reliability.

3. Neglecting Regular Servicing: The Lifeline of Your Weighbridge

Just like any complex machinery, regular servicing is absolutely imperative for the overall health and longevity of your weighbridge. Ignoring this vital practice can lead to premature wear and tear, costly breakdowns, and operational inefficiencies. Consistent maintenance helps proactively identify and address potential issues. When considering service, prioritize faster response times and expertise over mere proximity. Remember, weighbridge cost isn’t just the purchase price; it includes ongoing maintenance to ensure optimal performance and avoid larger, unforeseen expenses.

4. Ignoring a Weak Foundation: The Root of Future Problems

A compromised foundation can create a host of issues for your weighbridge machine. It’s crucial for clients to thoroughly consider the foundation requirements from the very beginning. If you’re uncertain about the best type of foundation for your weighbridge machine, or if your existing foundation requires repairs, don’t hesitate to seek expert assistance. We are always ready to address your queries and guide you towards the optimal solution.

5. Failing to Select the Correct Load Cells: Precision at Its Core

Choosing the right load cells is critical for accurate and reliable weighing. Always select a load cell with a capacity that comfortably exceeds your peak operational load. Furthermore, carefully identify the external elements the load cell will encounter. For example, for high-endurance applications, ensure the load cell possesses the appropriate rating. Opting for the best Electronic Weighing Machine with correctly matched load cells is an investment in precision and longevity.

6. Skipping Weighbridge Theft Prevention Software: Protecting Your Assets

Installing anti-theft software from reputable electronic weighbridge manufacturers can help weighbridges and dharamkanta operations reduce losses by as much as 50%. Many businesses incur significant losses due to the lack of this crucial safeguard. Several weighbridge providers now offer anti-theft software as an integrated solution. This software is an invaluable tool in today’s environment, providing robust protection against potential fraud and theft.

7. Overlooking Standard Weight Differences: The Calibration Conundrum

A common pitfall is neglecting regular calibration, which can lead to significant discrepancies in weighbridge readings. For instance, a weighbridge that is uncalibrated might read 950kg when a 1-tonne weight is placed on it. However, this small error can compound significantly at higher loads, potentially reading 9500kg when 10 tonnes are applied. At the higher end of the spectrum, this seemingly minor percentage off can culminate in a substantial 500kg difference! Always get your dharam kanta weighbridge price from a reputed provider and understand that investing in regular calibration is non-negotiable for accurate measurements.

How Tulsi Weigh Solutions Pvt. Ltd. Guides You: Your Partner in Precision Weighing

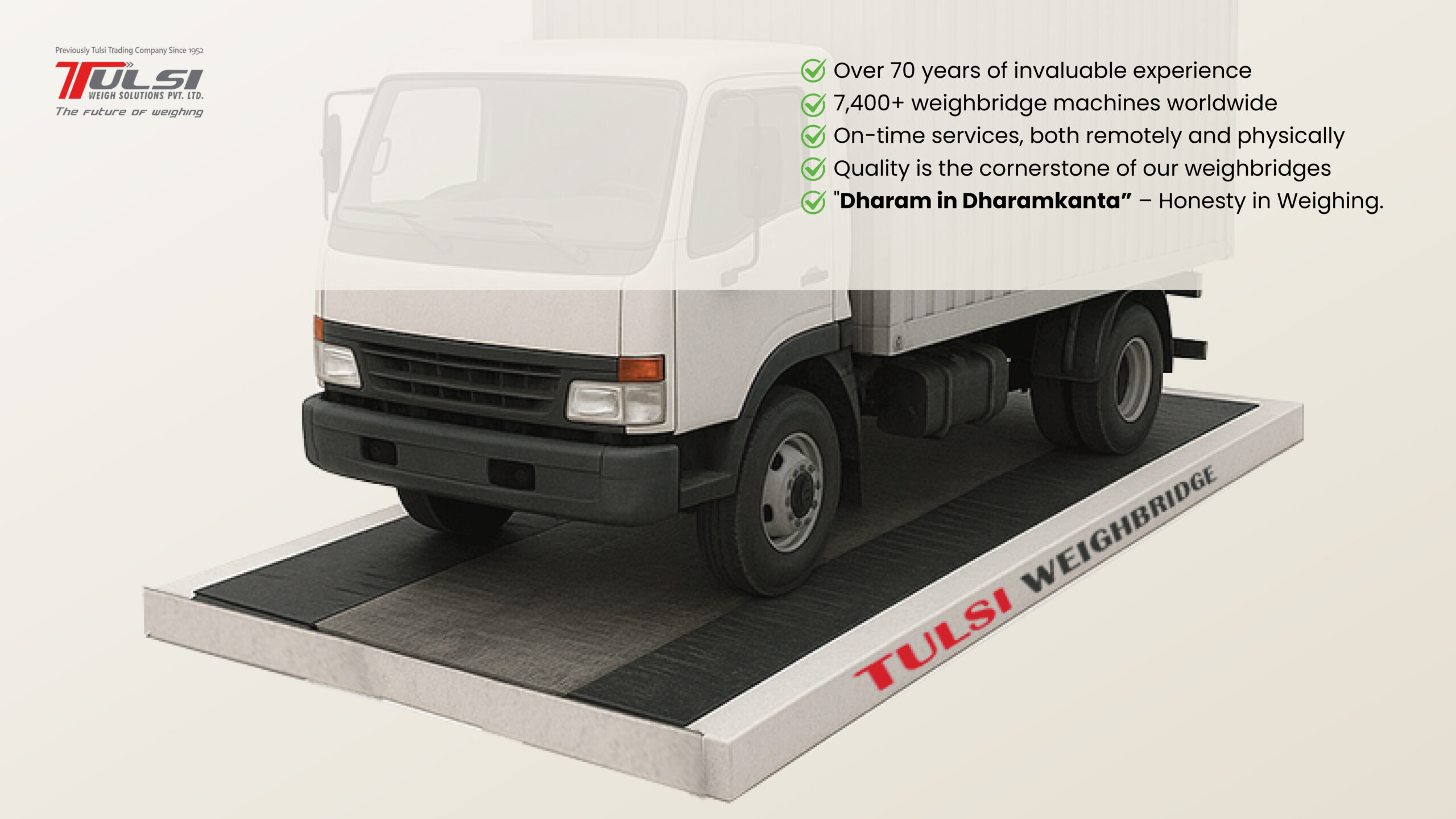

At Tulsi Weigh Solutions Pvt. Ltd., we stand as a premier weighbridge manufacturer with over 70 years of invaluable experience, having successfully supplied 7000+ weighbridge machines across India. Our core philosophy revolves around understanding and customizing machines to precisely meet our clients’ unique requirements.

We pride ourselves on providing on-time services, both remotely and physically, designed to swiftly resolve most issues and minimize downtime. Quality is the cornerstone of our weighbridges, a commitment proudly reflected in our esteemed clientele, including:

- Tata Tea

- Dalmia Group

- Shyam Steel

- Bajaj

- Rashmi Group

Our unwavering motto at Tulsi Weigh Solutions Pvt. Ltd. is simple yet profound: “Dharam in Dharamkanta – Honesty in Weighing.”