In this article we will discuss the different errors that can occur in a load cell. This is slightly technical and best understood in consultation with your weighing engineers.

The more you understand your load cell the better you can determine the dynamics of weighing.

This article will help you to understand different load cell errors and in turn, help you choose the right components and manage the environment that determines the final weight output displayed by your weighbridge.

Here we will be considering different factors that determine the final output from your load cell. It will be a good idea to consult with your weighing engineers to understand these factors better. This is going to help to zero down the right load cell that would fit your requirements.

The more you understand your load cell the better you can determine the dynamics of weighing.

Factor-1 – Error amplification

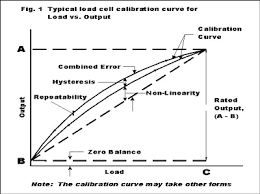

Load cells may amplify an error with an increase in weight. This is termed a non-linearity issue.

The impact of this issue can be best understood with an example. When you weigh a load of 200 kg let’s say the error of 10 kg is encountered. We at times assume that this error is constant. But to our surprise, we may find that when we weigh 2000 kg the error is also amplified 10 times. We may have calibrated the weighbridge to nullify 10kg but with the 2000kg measurement, the error of 90kg still remains in the measurement. This is surely not an error to be neglected.

There are load cells that are pre-calibrated to tackle such non-linearity errors. This is one of the major factors that differentiates load cells based on cost.

As a consumer, you may be startled by the price difference of load cells in the market. One major factor that drives the price of the load cell is determined by how well a load cell is handling such linearity issues.

Linearity issues are a major factor that determines the cost of load cells

Factor 2 – Hysteresis

Do you know that your load cell may have different readings for the same weigh applied to it? This differs is encountered when the load is increased to a specific weight and second when the weigh is being decreased to that weight. Technically it is called Hysteresis.

is encountered when the load is increased to a specific weight and second when the weigh is being decreased to that weight. Technically it is called Hysteresis.

This comes into effect when we need to fill a shipment to a particular weight or empty a container to a certain weight.

Most of the load cells are calibrated against hysteresis and linearity issues together and called a combined error.

Factor 3 – Error with time and frequency

Load cells may display some errors while repeatedly measuring weight. This is one factor that must be accounted for as well to mitigate any error in the final output.

Load cell also shows a difference with time, when the load remains on the cell for a long time. This is called the creep effect.

Factor 4 – Temperature changes

Temperature changes the sensitivity of the load cell. Most of the load cells are temperature-compensated to reduce errors.

But if the weighing cycle exposes the load cells to low temperature (at night) and high temperature in the day time is wise to account for errors due to temperature change.

How can Tulsi Weigh Solutions Pvt. Ltd. help you?

We are a weighbridge manufacturer company with 70+ years of experience, supplying 1000+ weighbridges all over India.

Tulsi experts will guide you on which load cell will suit your industry type and purpose. We provide high precision.

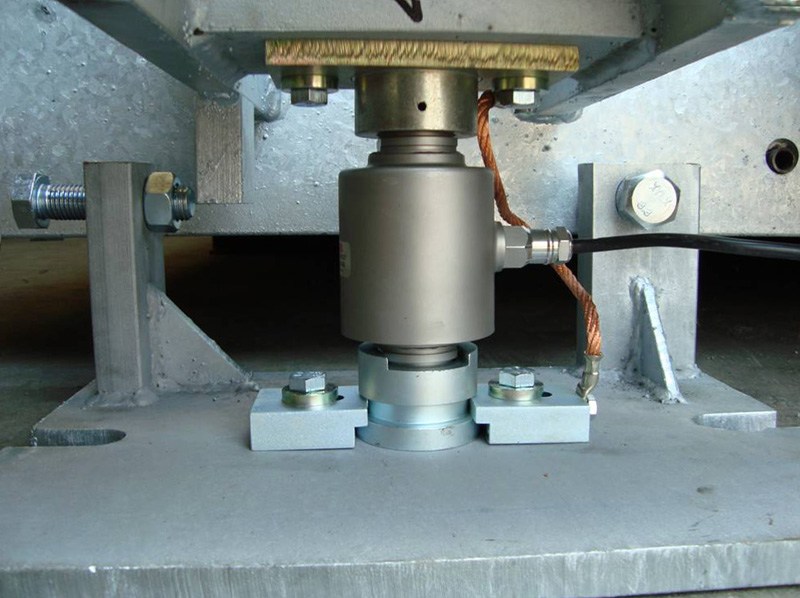

With respect to load cells, Tulsi supplies the best Bilancial load cells that allow a higher rate of thermal expansion without causing any fault in weight. It’s the most trusted modern-technology load cell brand to date.

We focus on client requirements and customize the machines accordingly. We provide on-time services both remotely and physically, which will ease most of the problems instantly. Quality is the main key to our weighbridges, and we’re proud to showcase the major clients we’ve dealt with.

- Tata tea

- Dalmia Group

- Shyam Steel

- Bajaj

- Rashmi Group